Industrial Manufacturing ERP Solutions by CiPert

In the fast-paced world of industrial manufacturing, efficiency, precision, and adaptability are key to staying ahead of the competition. CiPert’s advanced Cloud ERP solution is purpose-built to meet the challenges of modern manufacturing. From inventory management and production planning to quality control and real-time reporting, our solution empowers manufacturers to optimize operations, reduce costs, and drive sustainable growth.

A Complete CiPert Cloud ERP Suite for

Industrial Manufacturers

Advanced Features Tailored to Meet Your Unique Industry Needs

CiPert’s Manufacturing ERP Solution offers an all-inclusive suite designed to meet the diverse and complex needs of modern manufacturers. It combines core manufacturing, distribution, financial, and reporting functionalities with optional, seamlessly connected applications, allowing you to customize the system to suit your unique business operations.

Bill of Materials and Routing

Production Management

Material Requirements Planning (MRP)

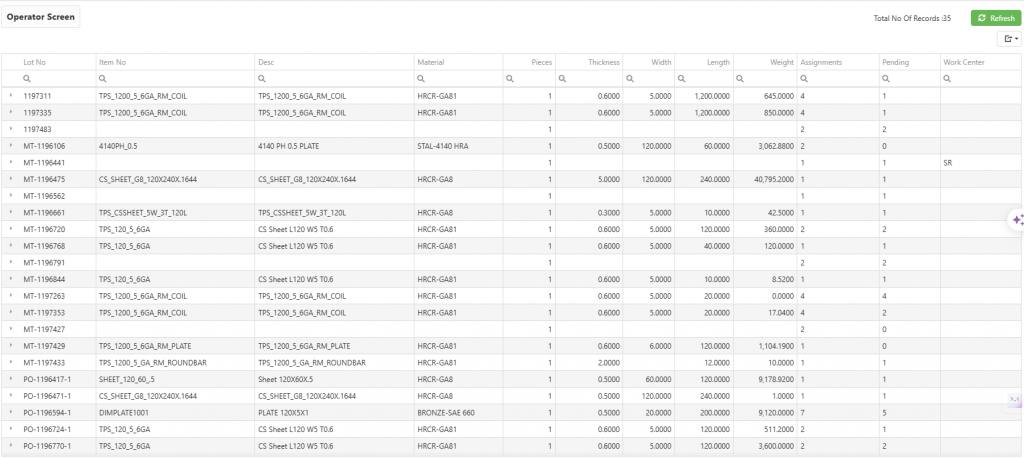

Inventory Management

Purchase Order Management

Sales Order Management

Advanced Planning and Scheduling (APS)

Requisition Management

Manufacturing Management

ERP Business Intelligence and Analytics

Product Configurator

Financial Management

Engineering Change Control (ECC)

Project Accounting

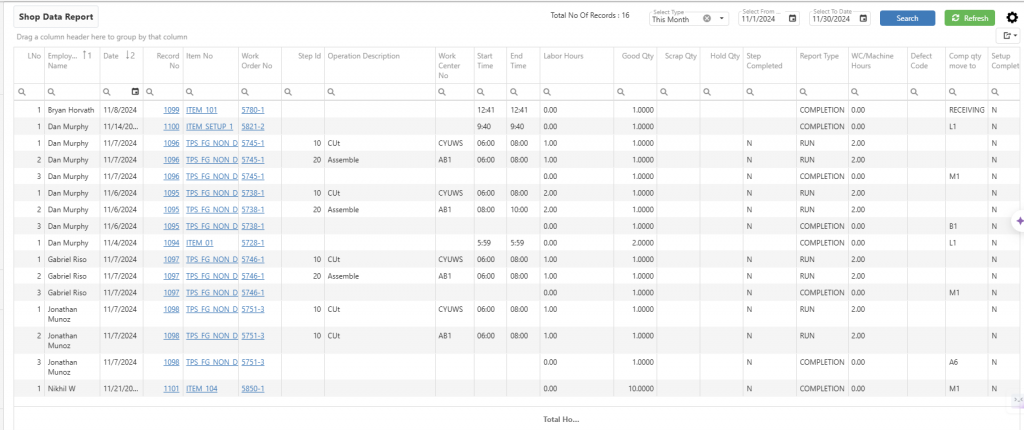

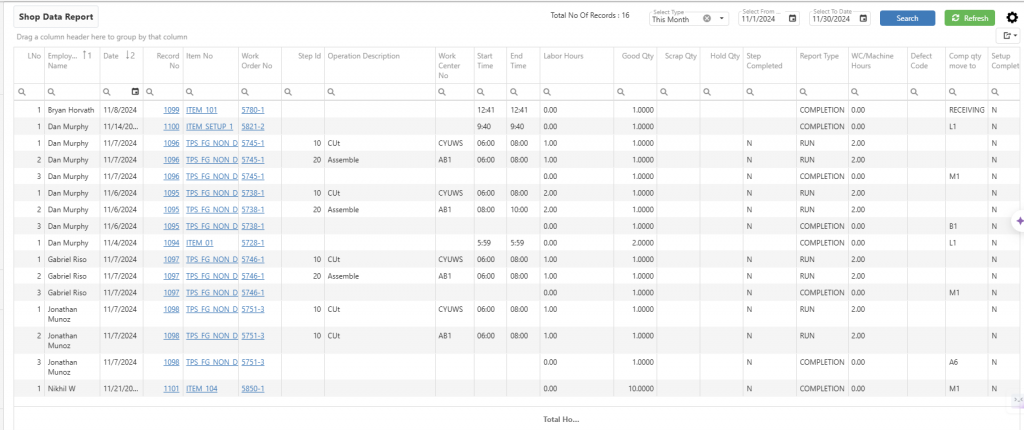

Manufacturing Data Collection (MDC)

CRM Integration

Service Management

Manufacturing Estimates

Flexible, Integrated, and Extensible Manufacturing ERP Software by CiPert

Efficient manufacturing demands dynamic solutions that can adapt to your processes, seamlessly integrate with your operations, and scale alongside your business growth.

CiPert’s Manufacturing ERP Software is designed to provide flexibility, scalability, and advanced tools to streamline operations, optimize efficiency, and enhance decision-making at every stage of your production journey.

Flexible Production Methods

Engineering and Design

Planning and Scheduling

CiPert’s Manufacturing ERP supports a wide range of production methodologies to suit diverse manufacturing needs, including:

CiPert’s ERP Software ensures every production methodology is optimized and scalable to meet evolving business demands.

Turn your innovative ideas into reality with CiPert’s advanced engineering and design capabilities.

Achieve optimal resource utilization with advanced planning and scheduling features

Have Questions? Reach Out To Us

Address

CiPert Inc

2451 W GRAPEVINE MILLS CIR

GRAPEVINE, TX 76051

info@cipert.com

Phone

408.418.5219