Bill of Materials:

Streamline Your Production Process with Accuracy and Efficiency

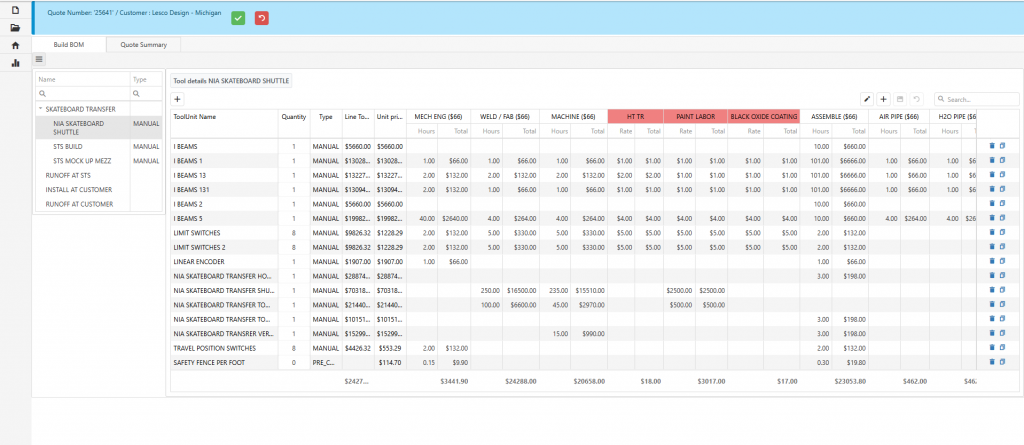

CiPert’s Bill of Materials (BOM) module is designed to help manufacturers and businesses manage complex production processes with ease. Gain full control over the creation, management, and modification of BOMs, ensuring accuracy, reducing errors, and optimizing your resources. Whether you’re handling simple or multi-level assemblies, CiPert provides the flexibility and real-time insights you need to scale your business.

Key Features

Multi-Level BOM Management:

Manage multi-level assemblies with ease, tracking each component, sub-assembly, and finished product through the entire production process.

Real-Time Updates:

Automatically update BOMs in real-time as changes occur, ensuring your production team always works with the most current data.

Cost Tracking:

Accurately track material costs, labor, and overhead associated with each BOM, helping you control costs and improve profitability.

Version Control:

Manage different versions of BOMs to keep track of product revisions, ensuring you maintain consistency and quality across production runs.

Material Requirements Planning (MRP) Integration:

Seamlessly integrate with CiPert’s MRP system to ensure materials are available when needed, reducing delays and optimizing production schedules.

Benefits of CiPert’s Bill of Materials Module

Improved Accuracy:

Ensure every component and resource is accounted for, minimizing production errors and rework.

Enhanced Efficiency:

Streamline production planning with clear, real-time data on material requirements, reducing bottlenecks and delays.

Cost Optimization:

Gain visibility into material and production costs, enabling better financial control and decision-making.

Greater Flexibility:

Easily adapt to changes in product design, material substitutions, or production methods with flexible BOM management tools.

Seamless Collaboration:

Share up-to-date BOM data across teams, ensuring engineering, production, and purchasing are always aligned.

How CiPert’s BOM Works

Create and Modify BOMs:

Quickly create detailed BOMs for products and assemblies, specifying materials, quantities, labor, and more.

Manage Multi-Level Assemblies:

For more complex products, manage nested BOMs that track components at each stage of the assembly process.

Monitor Costs and Availability:

Track costs for each BOM in real-time and ensure materials are available when needed with integrated MRP and inventory tracking.

Stay Compliant with Version Control:

Keep track of product revisions and maintain compliance with version-controlled BOMs.

Use Cases

Manufacturers:

Manage complex assemblies with real-time updates, version control, and cost tracking to ensure efficient production.

Engineering Teams:

Collaborate easily with production and purchasing teams by sharing up-to-date BOMs and tracking changes.

Purchasing Departments:

Ensure accurate material orders based on real-time BOM data, optimizing procurement and reducing excess inventory.

Have Questions? Reach Out To Us

Address

CiPert Inc

2451 W GRAPEVINE MILLS CIR

GRAPEVINE, TX 76051

info@cipert.com

Phone

408.418.5219